Product Details

| Product name | AR Fiberglass Roving | ||

| MOQ | ≥1000KG | ||

| Application | building & construction, telecommunication and insulator industry. Pultrusion profiles for outdoor sports equipment, Optic cables, Various sectional bars, etc. | ||

| Feature | 1. Alkali resistant fiberglass 2. Safe easy handling 3. Excellent mechanical performance 4. Easy blending into the GRC matrix 5. Easy spraying & chopping 6. Perfect for incorporation into complicated composite profiles and details | ||

PERFORMANCE ATTRIBUTES

ZBREHON Alkali resistant fiberglass have Excellent mechanical performance, Easy blending into the GRC matrix, Easy spraying & chopping and so on benefits.

Technical Data

| Type of glass | Alkali Resistant(AR) | ||

| Zirconia(zrO2) content | ≥16.7% | ||

| Filament diameter um | 13±2 | ||

| Strand tex | 76±8 | ||

| Roving tex | 2700±270 | ||

| Specific gravity | 2.7 g/m3 | ||

| Elastic modulus | 80.4 Gpa | ||

| Tensile strength | 1.7 GN/m2 | ||

| Moisture Content | ≤0.2% | ||

| Sizing Content | 0.8-2.0% | ||

| Breaking strength | ≥0.30 N/tex | ||

| Softening temperature | 860°c | ||

| Stiffness | ≥120mm | ||

| Fire resistance / material | incombustible inorganic material | ||

SUCCESSFUL CASES

AR-Glass has been used in concrete for decades and results in a lighter weight product since the reinforcement the fiberglass provides allows for a thinner concrete that doesn't require steel reinforcement. Countertops made from GFRC make use of AR-Glass fiberglass. However, it is not the only interior design element that uses this specific type of glass fiber. Other decorative applications also make use of this fiberglass type. One example is fireplace surrounds.ZBREHON AR Fiberglass Roving,which spray-up is similar to shotcrete in that the fluid concrete mixture (minus ARG fibers) is sprayed into the forms. The concrete is sprayed out of a gun-like nozzle that also chops and sprays a separate stream of long fibers. The concrete and fibers mix when they hit the form surface. ARG fiber is fed off of a spool in a continuous thread into the gun, where blades cut it just before it is sprayed. Chopped fiber lengths tend to be much longer (about 1.5") than fibers that get mixed in, since long fibers would ball up if they were mixed into the concrete before spraying.ZBREHON AR-Glass (alkali-resistant) is one of many types used for various fiberglass applications. Like many of the "letter named" glass types, the letter in the name refers to characteristics of the glass fiber used in the composite. AR-Glass fiberglass is a specific type among the types of fiberglass.Like most fiberglass, AR-Glass fiberglass is strong. In fact that is one of the reasons it is used. The strength relative to its weight makes it a highly effective and useful material for a variety of applications.Packaging & Storage

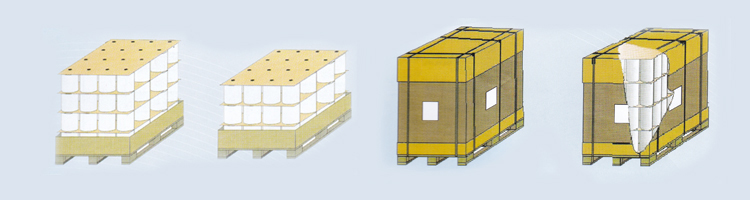

18±1kg/roll, individually shrunk film packaging (with weight tag); Each fumigated pallet has 3 or 4 levels with 16 rolls/ level, 48 rolls/small pallet, 64rolls/big pallet. It loads 20 pallets (Small & big pallet stacked in 2 layers) per 20 feet container, with a net weight 20tons. Note: AR Glassfibre roving pallet shall be stored dry in original packaging and advisable to stack in one layer, at a temperature between 15℃- 35℃ & relative humidity between 35%- 65%. If stored below 15℃, it is advisable to hold in workshop for 24 hours to prevent condensation before use.